The events of 2020 have seen a focus-shift across the industry with companies looking for opportunities to invest in and support other Australian-made and owned businesses. Universities are also eagerly seeking forward-thinking companies that can offer engineers stimulating internships and employment following graduation.

Award-winning wastewater treatment company creates opportunities

Australian wastewater treatment company, Aerofloat, has a reputation for not only creating opportunities for undergraduates but for nurturing and developing engineers that then excel in the workforce. The company is known for its innovative wastewater and sewage treatment systems and has won awards for its patented technology.

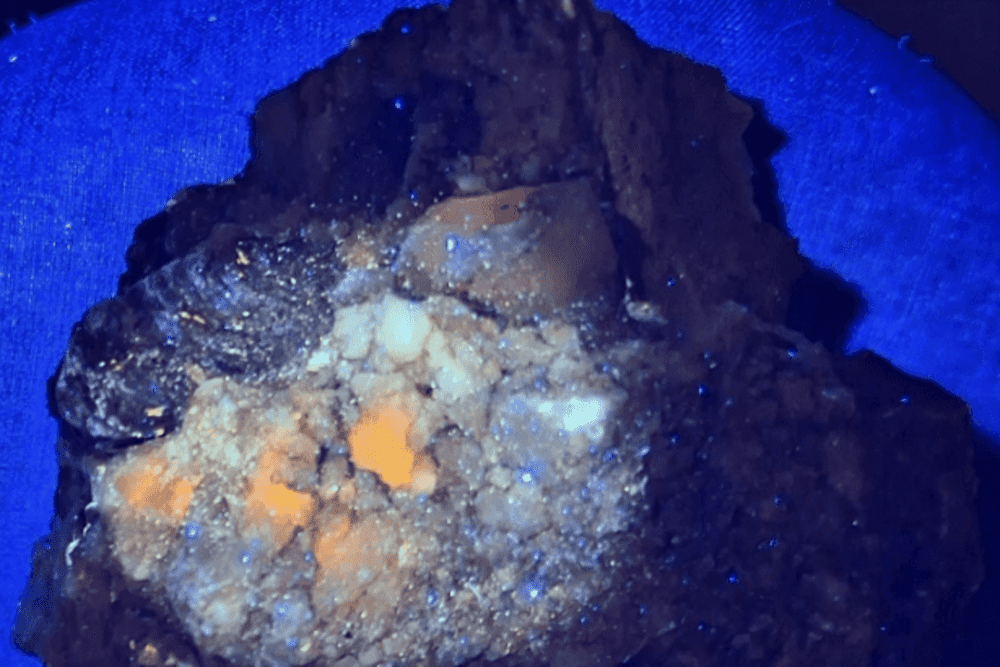

Aerofloat’s innovative designs have been integral in achieving outstanding effluent results across the mining, recycling and packaging industries, often where other wastewater treatment companies were unable to find a solution. Lightweight designs incorporate patented technology, and also create opportunities for water reuse (such as irrigation) and recycling.

Investing in students to help grow the sector

With innovation the driver of Aerofloat’s work in the sector, it comes as no surprise that the company has attracted high achieving university graduates and interns.

Santhosh Ramesh began an internship with Aerofloat in 2016 and has been employed as a full time engineer with the company since completing his studies in 2017. Ramesh’s interest in advanced water treatment and industrial wastewater recycling led him to undertake a Master of Engineering Science (Water, Wastewater and Waste Engineering). Ramesh is grateful for the opportunity Aerofloat gave him in his final year of studies.

“Working with Aerofloat gave me a unique opportunity to learn with true innovators in the sector. Not only was I privy to the logic and inspiration behind Aerofloat’s innovative technology, I was able to witness first-hand, the difference that level of technology can have on industry,” said Ramesh.

Ramesh worked with the Aerofloat team on three designated sites during his internship, allowing him to diversify his understanding of wastewater engineering. Working alongside the company’s head engineers, he was able to pursue his interests in chemical engineering and even more specifically, learning and specialising in biological wastewater technologies.

“Aerofloat’s internship gave me an engaging and real-time platform to study the effect of wastewater treatment chemistry. I was able to work with coagulants to help develop chemical blends that have an enormous impact on the resulting effluent quality – and in fact streamline chemical consumption,” said Ramesh. “I learnt to understand how variations in influent parameters can affect the wastewater treatment process and gained an in-depth knowledge of the role of pH in improving effluent results,” he added.

The internship also opened a network of like-minded engineers and industry providers to Ramesh. “I was also able to work with Aerofloat’s incredible network of suppliers, who were more than happy to share their knowledge with me. This in turn improved my understanding of how to optimise the wastewater treatment process, select the best chemicals, tools and parts,” said Ramesh. Ramesh is now an integral member of the Aerofloat team having been instrumental in the success of several projects, particularly thanks to his expertise in chemical engineering.

David Snowden also joined Aerofloat’s engineering team two years ago, following the completion of his internship with a well-known international engineering mining consultancy firm.

“Aerofloat gave me the opportunity to learn real-time problem-solving skills,” said Snowden. “I’ve worked on Aerofloat projects within Australia but also in Indonesia, where I helped install a large wastewater treatment plant. The opportunities and support Aerofloat’s head engineers have given me over the past two years have been tremendous,” said Snowden.

Aerofloat’s Operations Manager, Michael Anderson, nurtured Snowden’s talent for using advanced Computer Aided Engineering tools that are integral to the engineering design process. “Michael is well-known in the industry as an expert in 3D CAD modelling, so I’ve been very lucky to learn both 2D and 3D modelling from him,” said Snowden.

When asked if he has any advice for wannabe interns, Snowden said to be prepared for a steep learning curve, followed by a steep responsibility curve.

“Whilst Aerofloat’s head engineers have always been on hand to support me, the trust and commitment they gave me in those early months of my employment made a huge difference to my confidence. I learnt so much by being hands-on and by being able to voice my ideas in the design-making process. It’s an opportunity that I am very grateful for,” said Snowden.

Luke Parker undertook an internship with Aerofloat in 2019 that taught him to both design and manufacture parts, such as wastewater pipes. Aerofloat gave Parker the opportunity to pursue his interest in mechanical engineering with hands-on experiences under the guidance of his Aerofloat mentors.

“I was lucky to get the opportunity to work in Queensland with the Aerofloat team and really get my hands dirty, working with adjusting pipe sizes to create a solution. It was my first real insight into the front-end work of a project and was incredibly rewarding,” said Parker.

For employers, having an intern on-site helps increase available resources and build future team loyalty and longevity. For students, internships open opportunities for hands-on learning and support the work required by the university.

“My internship experience positively impacted on my studies and certainly in writing my university thesis. I used my new-found skills in Inventor 3D Modelling to design a product that was easy to manufacture and test, and ultimately meet my outcome goals,” said Parker. Parker says the experience Aerofloat has given him extends beyond knowledge-building. “I’ve learnt from everyone in the Aerofloat team – from the importance of design simplicity to work safety precautions. Working with driven, positive team members has been terrific too.”

Upskilling a sound investment

Investing in additional training for new employees fresh from university is essential for safe work practices and employee growth. Employers need to ensure that new team members are equipped to perform at the best of their abilities, safely and confidently. “It’s been a non-stop learning experience for us all,” said Snowden. “In addition to the in-house training and trade tools we’ve acquired, Aerofloat ensured we undertook a number of safety courses such as forklift handling, working at heights and working in confined spaces, and design safety courses,” added Parker.

Australian wastewater treatment company, Aerofloat, creates adaptable sewage treatment plant solution for mine sites and other remote locations. It also works heavily in the industrial wastewater treatment space, in particular, providing solutions for the packaging and recycling industry and food and beverage market. Aerofloat’s designs are simple, cost-effective, durable, easy to transport and include remote monitoring technology.

Developed over many decades, Aerofloat’s technology and patented solutions reflect the company’s innovative approach to wastewater and sewage treatment solutions to the challenges facing the mining, recycling and packaging industries.

Visit Aerofloat’s website HERE.